PDF(8140 KB)

PDF(8140 KB)

PDF(8140 KB)

PDF(8140 KB)

PDF(8140 KB)

PDF(8140 KB)

链式回转弹仓刚柔耦合动力学建模及特性分析

Rigid-flexible Coupling Dynamic Modeling and Characteristics Analysis of a Rotational Chain Magazine

考虑到装填系统轨道输送链具有链节大、负载大、速度大的特殊性,提出一种基于相对坐标法和板单元离散方式的刚柔耦合动力学建模方法。利用邻接体的相对运动关系推导出运动学方程及体坐标与铰坐标的转化关系,建立广义坐标为独立铰坐标的动力学方程。利用有限元方法,基于板单元理论将链节和弹筒离散化,以链节为例建立单个链节的刚柔耦合动力学方程,随后通过刚-柔运动约束形式,利用增广方程形式,建立轨道输送链系统的刚柔耦合动力学方程。基于此方法,建立某弹仓(闭式轨道输送链)轨道输送链和弹筒的刚柔耦合动力学方程,并在不同工况下将基于板单元离散的数值仿真与实验结果进行对比。基于建立的刚柔耦合动力学模型,分析弹仓传动构件支撑刚度、轨道间隙等因素对弹仓系统的影响。研究结果表明:数值仿真结果与实验结果的趋势基本一致;支撑刚度对系统动态响应的影响程度取决于动力系统的结构形式和受力形式;轨道间隙的变化对系统的动态特性具有较大的影响,在工程应用中需要合理控制间隙;上下轨道错位对弹仓动态特性影响较大,需要合理控制加工装配精度。

Considering the unique characteristics of the autoloader’s rail conveyor chain, such as large chain links, heavy load and high speed, a rigid-flexible coupljng dynamic modeling method based on the relative coordinate method and the plate element discretization method is proposed. The relative motion relationships of adjacent bodies are used to derive the kinematic equations and the transformation relationship between body coordinates and hinge coordinates, thereby establishing the dynamic equations with independent hinge coordinates as generalized coordinates. The finite element method is used to discretize the chain links and cartridge cases based on plate element theory. Taking the chain link as an example, the rigid-flexible coupling dynamic equations for a single chain link are established. Subsequently, the rigid-flexible coupling dynamic equations for the rail conveyor chain system are developed by applying the rigid-flexible motion constraints in the form of augmented equations. Based on this method, the rigid-flexible coupling dynamic equations of the rail conveyor chain and cartridge cases for a certain magazine are established. The numerical simulation based on plate element discretization is then compared with experimental results under different working conditions. The effects of factors such as the support stiffness of transmission components and rail clearance on the magazine system, are analyzed by using the proposed rigid-flexible coupling dynamic model. The research results indicate that the numerically simulated results are generally consistent with the experimental results. The influence of support stiffness on the system’s dynamic response depends on the structural form and force application of the power system. The change in rail clearance has a significant effect on the system’s dynamic characteristics, thus necessitating the reasonable control of clearance in engineering applications. The misalignment of the upper and lower rails has a considerable effect on the dynamic characteristics of the magazine, requiring the reasonable control of machining and assembly accuracy.

火炮 / 弹仓 / 中厚板理论 / 刚柔耦合 / 动力学 / 间隙 / 轨道错位 {{custom_keyword}} /

gun / magazine / mid-thickness plate theory / rigid-flexible coupling / dynamics / clearance / rail misalignment {{custom_keyword}} /

表1 构件的质量、惯量参数Table 1 Mass and inertia parameters of components |

| 构件 名称 | 质量/kg | 惯量/(kg·m2) | ||

|---|---|---|---|---|

| Ixx | Iyy | Izz | ||

| 链轮 | 16.629 | 2.00 | 2.00 | 1.82×10-2 |

| 链节 | 0.152 | 1.93×10-4 | 2.01×10-4 | 9.73×10-6 |

| 弹筒 | 8.58 | 0.791 | 0.807 | 3.11×10-2 |

| 滚轮 | 5.35×10-2 | 5.20×10-6 | 5.20×10-6 | 8.31×10-6 |

| 弹丸 | 45.1 | 2.48 | 2.48 | 0.168 |

| 注:Ixx、Iyy、Izz分别为绕x轴、y轴、z轴的转动惯量。 |

表2 不同柔性单元类型计算结果与实验的误差Table 2 Errors between calculated and experimental results for different types of flexible units |

| 空载、半载 与满载 | 板单元计算结果与 实验的误差 | 实体单元计算结果与 实验的误差 |

|---|---|---|

| 空载 | 0.8925 | 0.9038 |

| 半载 | 0.9362 | 0.9393 |

| 满载 | 0.9647 | 0.9676 |

表3 弹仓输入参数Table 3 Nominal values of magazine input parameters |

| 输入参数 | 名义值 | 输入参数 | 名义值 |

|---|---|---|---|

| 滚轮半径/mm | 15 | 链轮轴轴承支撑刚度/(N·m-1) | 5×109 |

| 链节长度/mm | 30 | 滚轮-轨道间隙/mm | 0.3 |

| 弹筒-弹丸间隙/mm | 0.5 | 链轮槽半径/mm | 15.5 |

| 滚轮与链轮的摩擦系数 | 0.3 | 弹性模量/MPa | 2.1×105 |

| 滚轮与轨道的摩擦系数 | 0.3 | 泊松比 | 0.3 |

| 上轨道纵向初始位置/mm | 0 | 下轨道纵向初始位置/mm | 0 |

| 上轨道横向初始位置/mm | 0 | 下轨道横向初始位置/mm | 0 |

图8 支撑刚度对弹仓驱动链轮角位移的影响Fig.8 The influence of support stiffness on the angular displacement of magazine drive sprocket |

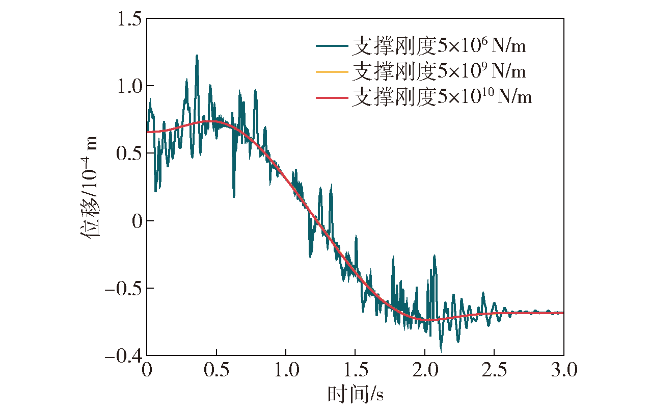

图9 支撑刚度对弹仓驱动链轮横向位移的影响Fig.9 The influence of support stiffness on the lateral displacement of magazine drive sprocket |

图10 支撑刚度对弹仓驱动链轮横向速度的影响Fig.10 The influence of support stiffness on the lateral velocity of magazine drive sprocket |

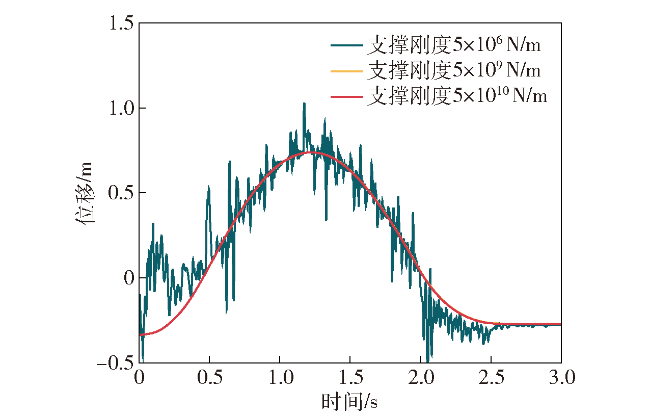

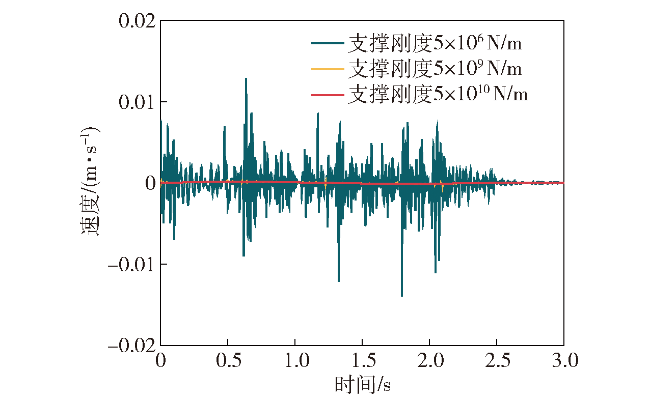

图11 支撑刚度对弹仓驱动链轮纵向位移的影响Fig.11 The influence of support stiffness on the longitudinal displacement of magazine drive sprocket |

图12 支撑刚度对弹仓驱动链轮纵向速度的影响Fig.12 The influence of support stiffness on the longitudinal velocity of magazine drive sprocket |

表4 支撑刚度对链轮运动的影响结果Table 4 The influence of support stiffness on the sprocket motion |

| 刚度/ (N·m-1) | 链轮角位移 (2.5s)/rad | 链轮横向位移 (2.07s)/m | 链轮横向速度 (2.043s)/(m·s-1) |

|---|---|---|---|

| 5×106 | 3.9886 | -2.64×10-5 | 0.0184 |

| 5×109 | 3.9837 | -7.33×10-5 | 1.87×10-5 |

| 5×1010 | 3.9824 | -7.34×10-5 | 2.7×10-6 |

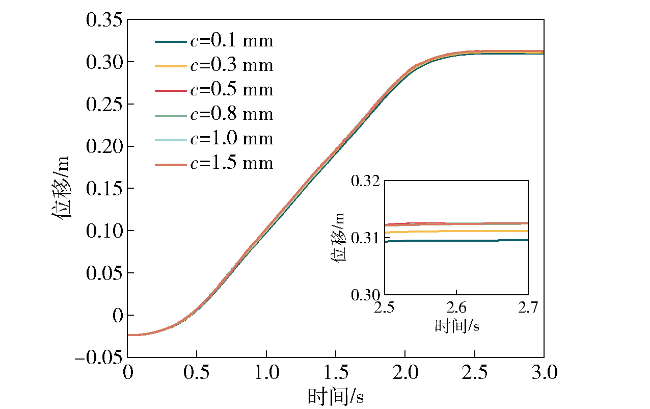

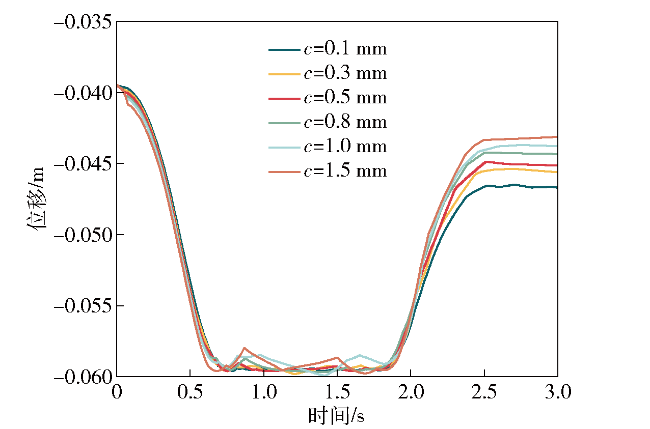

图13 轨道间隙对弹筒1位移的影响Fig.13 The influence of rail clearance on the displacement of magazine barrel 1 |

图14 轨道间隙对弹筒1横向位移的影响Fig.14 The influence of rail clearance on the lateral displacement of magazine barrel 1 |

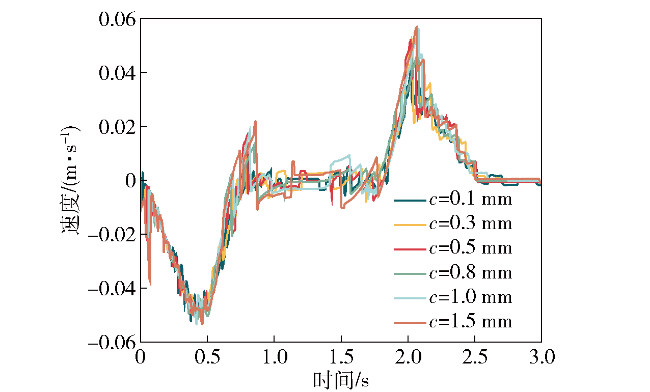

图15 轨道间隙对弹筒1横向速度的影响Fig.15 The influence of railclearance on the lateral velocity of magazine barrel 1 |

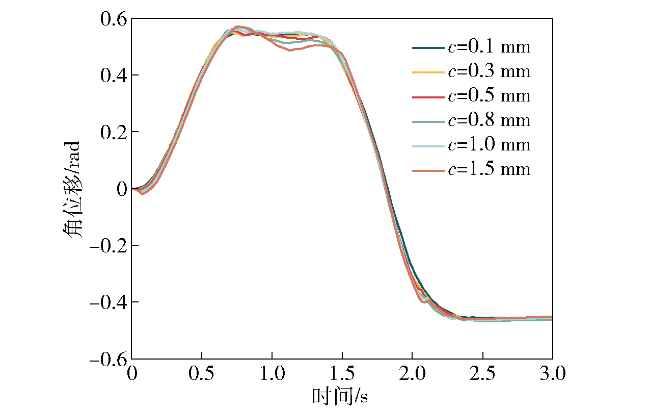

图16 轨道间隙对弹筒1转动角位移的影响Fig.16 The influence of rail clearance on the angular displacement of magazine barrel 1 |

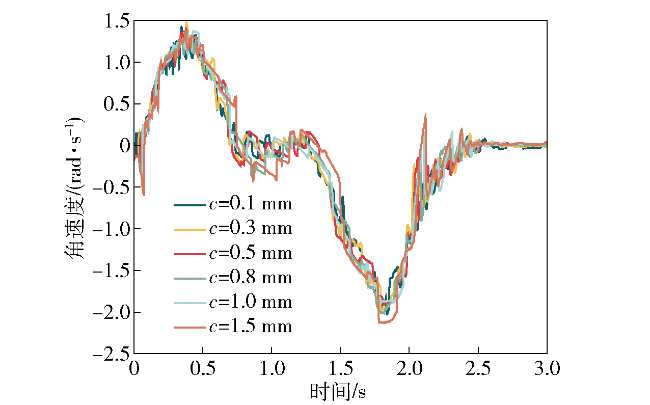

图17 轨道间隙对弹筒1转动角速度的影响Fig.17 The influence of rail clearance on the angular velocity of magazine barrel 1 |

表5 轨道间隙对弹筒运动的影响结果Table 5 The influence of rail clearance on the magazine barrel motion |

| 间隙/ mm | 弹筒1 位移 (3.0s)/ m | 弹筒1 横向位移 (3.0s)/ m | 弹筒1 横向速度 (2.0s)/ m | 弹筒1转 动角位移 (3.0s)/ m | 弹筒1转 动角速度 (3.0s)/ m |

|---|---|---|---|---|---|

| 0.1 | 0.3029 | -0.04672 | 0.03141 | -0.40068 | 0.02719 |

| 0.3 | 0.3109 | -0.04563 | 0.04223 | -0.46204 | -0.02007 |

| 0.5 | 0.3123 | -0.04515 | 0.04711 | -0.45678 | 0.01377 |

| 0.8 | 0.3124 | -0.04435 | 0.03350 | -0.46381 | -0.00474 |

| 1.0 | 0.3125 | -0.04379 | 0.03930 | -0.45623 | 0.01454 |

| 1.5 | 0.3126 | -0.04316 | 0.04355 | -0.45127 | 0.02767 |

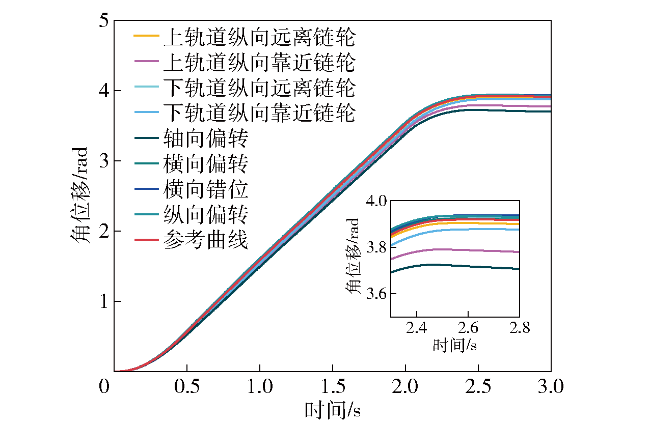

图18 轨道错位对链轮角位移的影响Fig.18 The effect of rail misalignment on the angular displacement of sprocket |

表6 轨道错位对链轮角位移到位的数值结果Table 6 The effect ofrail misalignment on the angular displacement in place of the sprocket |

| 影响因素 | 到位角位移/rad |

|---|---|

| 参考值 | 3.91195 |

| 上轨道纵向远离链轮 | 3.89348 |

| 上轨道纵向靠近链轮 | 3.77134 |

| 下轨道纵向远离链轮 | 3.92077 |

| 下轨道纵向靠近链轮 | 3.87183 |

| 轴向偏转 | 3.69871 |

| 横向偏转 | 3.91233 |

| 横向错位 | 3.9314 |

| 纵向偏转 | 3.9236 |

| [1] |

钱林方, 徐亚栋, 陈龙淼. 车载炮射击理论和方法[M]. 北京: 科学出版社, 2022.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [2] |

侯保林, 樵军谋, 刘琮敏. 火炮自动装填[M]. 北京: 兵器工业出版社, 2010.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [3] |

赵伟, 侯保林, 闫少军, 等. 链式回转弹仓区间不确定性动力学模型[J]. 兵工学报, 2024, 45(6): 1991-2002.

针对具有区间不确定性参数的辨识问题,提出一种基于区间可能度转换模型的区间不确定性参数的双层嵌套辨识(Double-layer Nested Identification,DNI)方法。通过将待辨识参数分为两类,利用DNI方法辨识出第1类确定性参数,再通过基于DNI思想的区间优化方法优化第2类区间不确定性参数的区间范围;面向嵌套策略类型方法计算量庞大且效率低的问题,选用贝叶斯优化-粒子群优化(Bayesian Optimization-Particle Swarm Optimization,BO-PSO)方法作为内层算法以提高求解效率。DNI方法的内层利用BO-PSO方法计算区间上下界,外层利用改进型布谷鸟搜索(Improved Cuckoo Search,ICS)方法辨识特定参数。为进一步缩短求解时间,提出一种ICS多核极限学习机(ICS-Multiple Kernel-Extreme Learning Machine,ICS-MK-ELM)代理模型,ICS-MK-ELM代理模型克服了人工调节每个核函数超参数的困难,并且模型预测精度明显高于核ELM(Kernel ELM,KELM)和MK-ELM;将DNI方法应用于链式回转弹仓的参数辨识,解决了链式弹仓具有区间不确定性参数的辨识困难的问题,参数辨识结果表明所提DNI方法以及基于DNI思想的区间优化方法具有更高的精度和稳定性。

For the identification problem with interval uncertain parameters, a double-layer nested identification (DNI) method based on an interval possibility degree transformation model is proposed. By dividing the parameters to be identified into two categories, the first type of deterministic parameters are identified by DNI method, and the interval range of the second type of interval uncertainty parameters is optimized by the DNI-based interval optimization method. The BO-PSO algorithm is chosen as the inner-layer algorithm to improve the efficiency of the nested strategy type method. For the inner layer of DNI method, BO-PSO method is used to calculate the upper and lower bounds of interval, and for the outer layer, ICS method is used to identify the specific parameters. In order to shorten the solving time, an ICS-MK-ELM agent model is proposed. The ICS-MK-ELM agent model overcomes the difficulty of manually adjusting the hyper-parameters of each kernel function, and the prediction precision of the model is obviously higher than those of KELM and MK-ELM. Finally, the DNI method is applied to the parameter identification of the rotational chain shell magazine, which solves the problem of the parameter identification of the chain-type magazine with interval uncertainty. The results of parameter identification show that the DNI method and the interval optimization method based on DNI have higher accuracy and stability. {{custom_citation.content}}

{{custom_citation.annotation}}

|

| [4] |

文浩, 侯保林, 林瑜斌, 等. 曲线链式回转弹仓动力学模型不确定参数辨识[J]. 兵工学报, 2024, 45(5): 1460-1471.

为了准确模拟曲线链式回转弹仓输送弹药过程中的非线性动力学特性,根据系统的拓扑结构和控制原理建立包含不确定参数的动力学模型。利用优化设计思想,基于系统测试数据建立不确定参数辨识模型。提出一种函数型时间序列相似度作为辨识准则,采用基于径向基函数的高维模型表示和径向基函数分别构建从机械系统和控制系统不确定参数到辨识准则的代理模型。将麻雀搜索算法嵌入岛屿模型进行多种群结构化,形成岛屿麻雀搜索算法,进行寻优求解。以工况1测试数据为基准,对机械系统和控制系统的不确定参数进行辨识。研究结果表明,辨识后的动力学模型对两种工况的输出结果与测试数据相似度较高,验证了建模的准确性和辨识的有效性,为动作可靠性分析和故障诊断研究提供了可靠的样本数据来源。

To accurately simulate the nonlinear dynamics of a curved chain rotary shell magazine during the delivery of ammunition, a dynamic model containing uncertain parameters is established according to the system topology and control principle. An uncertain parameter identification model for the dynamic model is developed based on the system test data using the optimization design idea. A functional time series similarity is proposed as the identification criterion. The high-dimensional model representation based on the radial basis function and the radial basis function are used to construct the surrogate models from the uncertain parameters of the mechanical and control systems to the identification criterion, respectively. The sparrow search algorithm is embedded into an island model for multi-population structuring to form an island sparrow search algorithm for optimization. The uncertain parameters of the mechanical and control systems are identified successively by taking the test data of working condition 1 as the benchmark. The results show that the outputs of the identified dynamic model for the two operating conditions are similar to the test data, which verifies the accuracy of modelling and the validity of identification, and provides a reliable sample data source for action reliability analysis and fault diagnosis research. {{custom_citation.content}}

{{custom_citation.annotation}}

|

| [5] |

马超超, 许金, 贾正荣, 等. 计及配合间隙的电磁发射重载链传动机构优化设计方法[J/OL]. 海军工程大学学报: 1-7 [2024-01-07]. http://kns.cnki.net/kcms/detail/42.1106.E.20231107.1417.010.html.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [6] |

陈冬, 钱林方, 陈志群, 等. 基于改进拟连续算法的回转弹仓位置控制[J]. 兵工学报, 2024, 45(5): 1436-1448.

为提高大口径火炮自动装填过程中回转弹仓工作的精确性和鲁棒性,在分析现有拟连续算法相关研究内容的基础上,设计一种全新的改进拟连续控制器对回转弹仓进行位置控制。通过与滑模扰动观测器相结合,新控制器增益不依赖于系统扰动的不确定性边界,且不需引入额外的控制器参数,降低了控制器的设计和调试难度。通过Lyapunov方程验证控制器本身及闭环系统的稳定性。仿真和试验结果表明:新设计的控制器相对于已有拟连续算法具有优越性,在受到不确定时变负载和不确定参数扰动的情况下,新设计的改进控制器在应用于回转弹仓时,在趋近段可以获得更快的收敛速度,减小到位超调量,并在滑动段有效减弱抖振。

Based on the existing researches on quasi-continuous algorithm, a novel improved quasi-continuous controller is designed to improve the precision and robustness of rotational shell magazine position control in the automatic loading process of a large caliber artillery.By combining a sliding mode disturbance observer, the novel controller is independent of the unknown system uncertainty boundary, and no new parameters are introduced, which will lower the difficulties of controller designing and adjusting.The stabilities of controller and close-loop scheme are verified by Lyapunov functions. The simulated and experimental results have demonstrated the superiority of the improved controller over the existing quasi-continuous algorithm.In the presence of unknown time-varying disturbance and uncertain parameters, the improved controller could achieve a higher convergence rate in reaching phase, reduce the overshoot and restrain chattering in sliding phase while performed on the magazine. {{custom_citation.content}}

{{custom_citation.annotation}}

|

| [7] |

鲍丹, 卫俞凯, 金鑫, 等. 考虑输出约束和输入饱和的弹仓自适应控制[J]. 兵工学报, 2024, 45(3): 789-797.

针对存在参数不确定性和外部扰动的某链式回转弹仓的位置跟踪控制问题,提出一种自适应控制方案。该方案基于神经模糊系统(Neuro-Fuzzy System, NFS)、非线性扰动观测器(Nonlinear Disturbance Observer, NDO)及障碍Lyapunov函数(Barrier Lyapunov Function, BLF),在实现高精度控制的同时满足输出约束和输入饱和的工程条件。通过BLF的设计,保证弹仓的位移跟踪误差约束在给定范围内。结合神经网络的函数逼近能力和模糊逻辑系统的推理能力,用于估计系统中的不确定性,减小对模型的依赖;两者结合的NFS作为NDO的一部分,进一步补偿估计误差和外部扰动,提高控制性能。此外,控制器设计考虑了运动过程中的执行器输入饱和问题。仿真结果表明,所设计的控制器在3种典型工况以及系统参数变化情况下均可实现弹仓的高精度位置跟踪控制,满足系统的约束条件。

An adaptive control scheme is proposed for the position tracking control of a chain rotary magazine with parameter uncertainties and external disturbances. Based on neuro-fuzzy system ( NFS), nonlinear disturbance observer (NDO), and barrier Lyapunov function (BLF), the proposed scheme achieves high precision control while satisfying the engineering conditions of output constraint and input saturation. The BLF design ensures that the position tracking error of magazine is constrained within a bounded range. The function approximation ability of neural network and the reasoning ability of fuzzy logic system are combined to estimate the uncertainties of the system and reduce the dependence on the model. The combined NFS is used as part of NDO to further compensate for estimation errors and external disturbances and improve the control performance. In addition, the actuator input saturation problem is considered in the design of the controller. The simulated results show that the designed controller can realize the high-precision position tracking control of the magazine under three typical working conditions and system parameter changes, and meet the constraints of the system. {{custom_citation.content}}

{{custom_citation.annotation}}

|

| [8] |

郝驰宇, 冯广斌, 闫鹏程, 等. 基于MFBD的输弹机刚柔耦合动力学建模及仿真分析[J]. 振动与冲击, 2016, 35(15):161-167.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [9] |

闫鹏程, 郝驰宇, 孙华刚, 等. 基于RecurDyn的开式链传动输弹机动力学联合仿真研究[J]. 火炮发射与控制学报, 2015, 36(2):31-35.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [10] |

陆栋栋. 重型单向齿形推弹链的设计研究[D]. 南京: 南京理工大学, 2016.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [11] |

李伟, 马吉胜, 狄长春, 等. 考虑参数随机性的供输弹系统动力学及动作可靠性仿真研究[J]. 兵工学报, 2012, 33(6):747-752.

利用MSC.Adams和Easy5仿真软件建立了供输弹系统机电液耦合的动力学模型,通过VV&A证明了仿真模型的可信度。针对MCS求解复杂结构系统随机动力学问题时计算量过于庞大的难点,提出了虚拟样机—蒙特卡洛模拟法—支持向量机(VP-MCS-SVM)动力学随机响应求解方法,高效地完成了供输弹系统随机动力学的仿真求解。结合统计推断理论和可靠性分析理论探讨了供输弹系统动作可靠性及随机参数分布特征漂移时的动作可靠性问题利用MSC.Adams和Easy5仿真软件建立了供输弹系统机电液耦合的动力学模型,通过VV&A证明了仿真模型的可信度。针对MCS求解复杂结构系统随机动力学问题时计算量过于庞大的难点,提出了虚拟样机—蒙特卡洛模拟法—支持向量机(VP-MCS-SVM)动力学随机响应求解方法,高效地完成了供输弹系统随机动力学的仿真求解。结合统计推断理论和可靠性分析理论探讨了供输弹系统动作可靠性及随机参数分布特征漂移时的动作可靠性问题为复杂系统动作可靠性的评估提供了新的思路。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [12] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [13] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [14] |

张雷雨, 李剑锋, 杨洋. 装甲车辆用立式弹药舱的设计与动力学分析[J]. 兵工学报 2017, 38(5): 843-851.

为分析输送链条的动力学特性和弹药的稳定性,将所有链节及弹架两侧双排滚子简化为弹簧阻尼单元,采用多体系统动力学和运动弹性动力学理论,建立输送链条的完整动力学模型和弹药的稳定性模型。借助Matlab软件,对输送链条的整体动力学模型进行数值仿真,并求解弹药的稳定性模型。通过数值仿真结果可知:在不同驱动功率下输送链条的速度、加速度均窄幅波动;轨迹线的形状特征决定了弹药离心力的动力学响应和突变特性,离心力的突变特性对弹药运动法线方向稳定性具有较大的影响,而弹药在运动切线方向上的稳定性主要受自身惯性和输送链条的动力学参数影响。根据弹药上部的摆动位移响应可知,弹药在运动法线方向和切线方向具有较好的动态稳定性。采用试验测量方法,得到输送链条的切线方向加速度与弹架的法线方向加速度值,测量数据与仿真结果较为吻合。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [15] |

王光建, 姜铁牛. 弹链系统间隙铰多体动力学模型仿真与试验[J]. 机械工程学报, 2008, 44(5): 238-241.

传统的弹链系统力学模型,常常简化为平面内的运动,此模型对于分析弹链系统的横向运动、窜弹等问题有局限性。研究具有螺旋导引的弹链系统纵向和横向运动规律;建立含间隙铰碰撞的多体动力学模型;用等效弹簧阻尼模型对弹链系统的碰撞和接触进行模拟;对上述模型进行仿真和试验,结果表明:该力学模型能够较真实反映系统的运动规律,能对弹链系统的运动进行很好的预测和分析。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [16] |

刘太素, 钱林方, 陈光宋, 等. 某输弹机开式链传动建模及动力学特性分析[J]. 兵工学报, 2018, 39(11): 2109-2117.

为分析某输弹机开式链传动机构在工作过程中的运动学精度和动力学特性,描述了滚轮与链轮齿槽之间的几何关系和接触模式以及链节之间的接触。针对不同的接触位置和接触模式分别建立了法向接触力模型和平面接触力模型,建立了某输弹机开式链传动机构多刚体动力学模型。分析了不同滚轮与链轮齿槽之间的接触特性,讨论了滚轮与链轮齿槽之间间隙变化对系统运动学精度及动力学特性的影响。研究结果表明:滚轮与链轮齿槽之间间隙的存在及大小变化对某输弹机开式链传动机构动力学特性具有很大影响,在工程实际中需要合理控制间隙。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [17] |

魏继卿, 许耀峰, 刘小蒙, 等. 自动弹仓回转选弹动力学仿真及优化[J]. 火炮发射与控制学报 2015, 36(2): 36-39.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [18] |

胡胜海, 郭彬, 邓坤秀, 等. 含非线性接触碰撞的大口径舰炮弹链柔性铰多体模型[J]. 哈尔滨工程大学学报, 2011, 32(9): 1217-1222.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [19] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [20] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [21] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [22] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [23] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [24] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [25] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [26] |

陈光宋. 弹炮耦合系统动力学及关键参数识别研究[D]. 南京: 南京理工大学, 2016.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

PDF(8140 KB)

PDF(8140 KB)

图1 弹仓结构组成

图1 弹仓结构组成 图2 弹仓主要结构拓扑关系

图2 弹仓主要结构拓扑关系 表1 构件的质量、惯量参数

表1 构件的质量、惯量参数 图3 变形挠度和转角的方向

图3 变形挠度和转角的方向 图4 刚柔耦合示意图

图4 刚柔耦合示意图 图5 某弹仓实验台架

图5 某弹仓实验台架 图6 某弹仓仿真和实验结果对比

图6 某弹仓仿真和实验结果对比 表2 不同柔性单元类型计算结果与实验的误差

表2 不同柔性单元类型计算结果与实验的误差 表3 弹仓输入参数

表3 弹仓输入参数 图7 弹筒和链节刚性和柔性时弹丸质心加速度对比

图7 弹筒和链节刚性和柔性时弹丸质心加速度对比 图8 支撑刚度对弹仓驱动链轮角位移的影响

图8 支撑刚度对弹仓驱动链轮角位移的影响 图9 支撑刚度对弹仓驱动链轮横向位移的影响

图9 支撑刚度对弹仓驱动链轮横向位移的影响 图10 支撑刚度对弹仓驱动链轮横向速度的影响

图10 支撑刚度对弹仓驱动链轮横向速度的影响 图11 支撑刚度对弹仓驱动链轮纵向位移的影响

图11 支撑刚度对弹仓驱动链轮纵向位移的影响 图12 支撑刚度对弹仓驱动链轮纵向速度的影响

图12 支撑刚度对弹仓驱动链轮纵向速度的影响 表4 支撑刚度对链轮运动的影响结果

表4 支撑刚度对链轮运动的影响结果 图13 轨道间隙对弹筒1位移的影响

图13 轨道间隙对弹筒1位移的影响 图14 轨道间隙对弹筒1横向位移的影响

图14 轨道间隙对弹筒1横向位移的影响 图15 轨道间隙对弹筒1横向速度的影响

图15 轨道间隙对弹筒1横向速度的影响 图16 轨道间隙对弹筒1转动角位移的影响

图16 轨道间隙对弹筒1转动角位移的影响 图17 轨道间隙对弹筒1转动角速度的影响

图17 轨道间隙对弹筒1转动角速度的影响 表5 轨道间隙对弹筒运动的影响结果

表5 轨道间隙对弹筒运动的影响结果 图18 轨道错位对链轮角位移的影响

图18 轨道错位对链轮角位移的影响 表6 轨道错位对链轮角位移到位的数值结果

表6 轨道错位对链轮角位移到位的数值结果/

| 〈 |

|

〉 |