-

Sponsored by: China Association for Science and Technology (CAST)

Editor-In-Chief: Xu Yida

ISSN 1000-1093

-

Hosted By: China Ordnance Society

Published By: Acta Armamentarii

CN 11-2176/TJ

Behaviors of Metal-based Reactive Fragments Penetrating Spaced Aluminum Targets

ZHOU Sheng;ZHANG Jiahao;YU Qingbo

Sponsored by: China Association for Science and Technology (CAST)

Editor-In-Chief: Xu Yida

ISSN 1000-1093

Hosted By: China Ordnance Society

Published By: Acta Armamentarii

CN 11-2176/TJ

Behaviors of Metal-based Reactive Fragments Penetrating Spaced Aluminum Targets

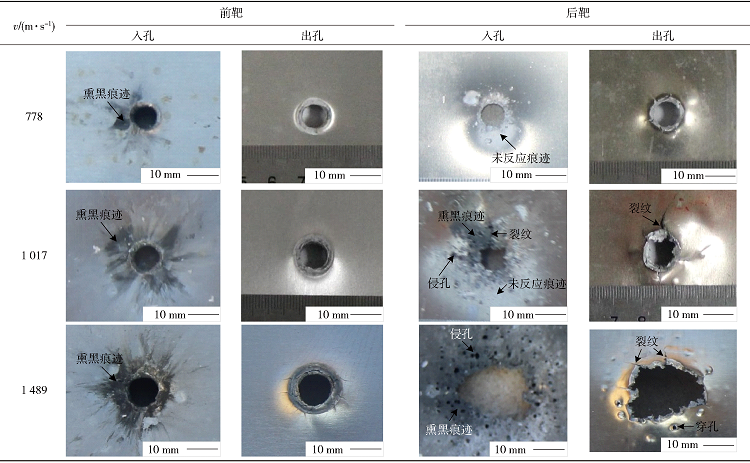

Ballistic impact experiments are conducted on metal-based reactive fragments impacting spaced targets to investigate the post-target debris cloud and damage effect behaviors of the reactive fragments, and to reveal the mechanism of their penetration. By observing the perforation mode of spaced target and the action behavior of fragments, we combine the breakage theory of target penetration, energy conservation law, and the reactivation response behaviors of reactive fragments to analyze and discuss the behaviors of reactive fragments penetrating spacer aluminum targets. The results show that the front target is plugging, and the rear target mainly presents the composite mode of center penetration and debris impact due to the kinetic energy-chemical energy coupling damage of post-target debris cloud. With increasing impact velocity, the reactive of reactive fragments increases. The theoretical model of the reactive fragments’ post-target debris cloud is established, and the evolution law of debris cloud is obtained. At different impact velocities, the unit debris kinetic energy is negatively correlated with unit reaction mass at the position of the critical through aperture.

metal-based reactive fragments / spaced aluminum targets / ballistic gun experiment / debris cloud {{custom_keyword}} /

Fig.1 Reactive fragments and quasi-static compressive stress-strain curves图1 活性破片及其准静态压缩应力-应变曲线 |

Table 1 Mechanical properties of reactive fragments表1 活性破片力学性能参数 |

| 弹性模量/GPa | 屈服强度/MPa | 断裂强度/MPa | 断裂延伸率/% |

|---|---|---|---|

| 21 | 1128 | 1568 | 10.1 |

Table 2 Image of typical target damage area表2 典型靶板毁伤区域图片 |

|

Table 3 Experimental results of reactive fragments damage to spacer target表3 活性破片侵彻间隔靶毁伤面积及穿孔情况实验数据 |

| 序号 | 碰撞速度/ (m·s-1) | 破片截 面积/mm2 | 前靶毁伤 面积/mm2 | 前靶穿孔 模式 | 后靶毁伤 面积/mm2 | 贯穿孔 半径/mm | 毁伤区 半径/mm | 后靶穿孔 模式 |

|---|---|---|---|---|---|---|---|---|

| 1 | 778 | 50.2655 | 64.3774 | 冲塞型 | 50.2359 | 4.12 | 7.50 | 花瓣型 |

| 2 | 780 | 50.2655 | 63.2158 | 冲塞型 | 50.4183 | 4.12 | 7.51 | 花瓣型 |

| 3 | 1017 | 50.2655 | 54.6541 | 冲塞型 | 71.2300 | 5.30 | 16.00 | 花瓣型 |

| 4 | 1024 | 50.2655 | 55.1223 | 冲塞型 | 72.6291 | 5.32 | 16.04 | 花瓣型 |

| 5 | 1489 | 50.2655 | 86.5922 | 冲塞型 | 332.3194 | 11.00 | 31.49 | 花瓣型 |

| 6 | 1493 | 50.2655 | 86.9156 | 冲塞型 | 334.4931 | 11.10 | 34.51 | 花瓣型 |

| [1] |

肖艳文, 徐峰悦, 余庆波, 等. 类钢密度活性材料弹丸撞击铝靶行为实验研究[J]. 兵工学报, 2016, 37(6):1016-1022.

采用弹道碰撞实验对类钢密度冷压成型和烧结硬化聚四氟乙烯/铝/钨系活性材料弹丸撞击铝靶行为进行了研究。基于圆柱形活性材料弹丸正碰撞不同厚度2A12硬铝靶的弹道极限速度、穿孔破坏模式及平均穿孔尺寸实验结果,结合THOR侵彻方程,得到活性材料弹丸正碰撞铝靶的弹道极限速度半经验关系,并分析铝靶厚度对活性材料弹丸相对于钢弹丸侵彻行为及性能的影响。从活性材料内部压力分布、靶板背面稀疏波卸载效应和活性材料激活响应点火时间等角度,分析和讨论了活性材料弹丸化学响应行为对侵彻性能的影响机理。分析结果表明,随着靶板厚度的增大,活性材料激活率和侵孔内爆燃压力随之提高,从而导致侵彻末端爆裂穿孔能力的显著增强。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [2] |

王海福, 郑元枫, 余庆波, 等. 活性破片引燃航空煤油实验研究[J]. 兵工学报, 2012, 33(9):1148-1152.

进行弹道炮发射实验,研究活性破片和钨合金破片作用模拟油箱和引燃航空煤油问题。实验结果表明:在1 080 m/s着速下,活性破片击穿10 mm厚LY12铝靶后能可靠引燃航空煤油,而同质量钨合金破片以1 643 m/s的速度命中油箱,只造成油箱穿孔及漏油,未能引燃燃油;常温状态下,活性破片较钨合金破片具有更强的引燃航空煤油能力,活性破片的内爆作用和化学能释放是造成油箱结构严重破坏和燃油燃烧的主要原因。进行弹道炮发射实验,研究活性破片和钨合金破片作用模拟油箱和引燃航空煤油问题。实验结果表明:在1 080 m/s着速下,活性破片击穿10 mm厚LY12铝靶后能可靠引燃航空煤油,而同质量钨合金破片以1 643 m/s的速度命中油箱,只造成油箱穿孔及漏油,未能引燃燃油;常温状态下,活性破片较钨合金破片具有更强的引燃航空煤油能力,活性破片的内爆作用和化学能释放是造成油箱结构严重破坏和燃油燃烧的主要原因。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [3] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [4] |

赵宏伟, 余庆波, 邓斌, 等. 活性破片终点毁伤威力试验研究[J]. 北京理工大学学报, 2020, 40(4):375-381.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [5] |

陈思源, 王在成, 仝远. PTFE基含能破片的能量释放特性研究[J]. 北京理工大学学报, 2017, 37(增刊2):62-65.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [6] |

王在成, 李姝妍, 姜春兰, 等. 高Al含量PTFE基材料爆炸冲击压缩特性及反应行为[J]. 北京理工大学学报, 2021, 41(4):356-363.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [7] |

李鑫, 王伟力, 梁争峰, 等. 复合结构活性破片对双层靶标毁伤效应[J]. 兵工学报, 2021, 42(4):764-772.

It is of great significance to study the damage power of reactive fragments which can withstand the loading of explosive. The damage effect of Al/PTFE composite structural reactive fragments on the different types of double-layer targets is studied through the loading experiment with 14.5 mm ballistic gun. The empiricial formulas of penetration diameter in front layer plate and expanding perforation area on rear layer plate were established using multiple regression analysis. The results show that the penetration diameter in front layer steel or aluminum plate increases with the rising of impact velocity and target thickness in the range of 800-1 400 m/s. The penetration diameters in the steel, aluminum and carbon fiber composite plates are 1.25-1.62 times, 1.08-1.42 times and 1.13 times of fragment diameter, respectively. Expanding and tearing damages are caused to the rear layer aluminum plate or the carbon fiber composite plate by the ractive fragments. The expanding perforation area increases with the increase in front layer target strength and impact velocity, and the delamination of carbon fiber and resin matrix for the back of carbon fiber composite plate should be considered in damage assessment. The empiricial formulas were proved to be accurate and reliable, and the relative error was controlled within 5% through experiment.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [8] |

徐光泽, 张良, 张兴高, 等. 活性破片侵彻Q235钢靶穿燃后效实验研究[J]. 火工品, 2021(2):19-22.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [9] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [10] |

陈进, 梁争峰, 周涛. 金属型活性破片战斗部技术研究进展[J]. 飞航导弹, 2019(4):89-95.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [11] |

曹召勋, 王军, 徐永东, 等. Al-Ni活性金属材料力学性能及其释能行为研究[J]. 兵器材料科学与工程, 2018, 41(5):90-96.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [12] |

陈元建, 陈进, 王军, 等. Al-Ni-W活性材料动态力学行为及其释能特性[J]. 兵器材料科学与工程, 2018, 41(4):71-75.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [13] |

刘晓俊, 任会兰, 宁建国. Zr-W多功能含能结构材料的制备及动态压缩特性[J]. 复合材料学报, 2016, 33(10):2297-2303.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [14] |

陈伟, 赵文天, 王健. 钨锆合金破片毁伤过程研究[J]. 兵器材料科学与工程, 2009, 32(2):108-111.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [15] |

王璐瑶, 蒋建伟, 李梅. 钨锆铪合金活性破片对间隔靶耦合毁伤特性[J]. 兵工学报, 2020, 41(增刊2):144-148.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [16] |

王璐瑶, 蒋建伟, 李梅, 等. 钨锆铪活性合金破片冲击释能行为实验研究[J]. 兵工学报, 2019, 40(8):1603-1610.

为研究活性合金材料的冲击释能行为,采用弹道枪驱动一种高强度、高密度的钨锆铪活性合金破片,使其以不同着速撞击Q235钢靶,通过观察靶板穿孔模式和靶后冲击释能火光区的高速摄影图像,提出合金类破片冲击释能的3阶段模型,即冲击激活阶段、自蔓延释能阶段、自激活阶段。结合应力波、热应力理论和冲击温升方程,获得该破片能量的激活门限、能量完全释放的临界条件、释能火光区的最大尺寸及其靶后有效毁伤距离。研究结果表明:钨锆铪活性合金破片不仅具有类似惰性破片的动能毁伤能力,而且在穿靶前活性能耗极小,活性能量在穿靶后毫秒量级内完全释放;破片活性能量被完全激活前,释能火光区的最大毁伤容积和有效毁伤距离分别随破片着速的提高呈指数和线性增长趋势。

To investigate the energy release behavior of reactive material under impacting conditions, a high-strength and high-density tungsten-zirconium-hafnium active alloy fragment is driven to impact the Q235 steel target at different speeds by a ballistic gun. A three-stage, including shock activation, self-propagation energy release, and secondary self-activation, model of impact-release energy of alloy fragments is proposed by observing the perforation pattern of steel target and the high-speed photographic image of the post-target impact-release fire zone.The activation threshold of fragment energy, the critical condition of complete energy release, the maximum size of energy release flare region and the effective damage distance behind the target were obtained by applying stress wave, thermal stress theory and shock temperature rise equation. The results show that the tungsten-zirconium-hafnium active alloy fragment not only has the kinetic energy damage ability similar to the inert fragment, but also has a little active energy consumption before the target is penetrated, and the active energy is completely released in a millisecond time regime after penetrating into the target. Before the fragmentation active energy is fully activated, the maximum damage volume and effective damage distance in the release energy flare region increase exponentially and linearly with the increase in fragmentation speed. Key

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [17] |

李梅, 王璐瑶, 蒋建伟. 典型反应性合金冲击释能量及耦合毁伤能力对比[J]. 兵工学报, 2021, 42(9):1867-1876.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [18] |

卢冠成, 曹康, 耿宝群, 等. 活性破片爆裂毁伤后效快速图像识别方法[C]//第12届全国爆炸力学学术会议论文集. 桐乡: 中国力学学会, 2018.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [19] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [20] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [21] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [22] |

刘沫言. 带壳装药的破片撞击和冲击波感度研究[D]. 沈阳: 沈阳理工大学, 2020.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [23] |

This paper studies the ballistic limit velocity of empty rectangular columns under a blunt projectile penetration, theoretically and numerically. The deformation mechanism of the empty column is considered as plugging. The projectile is assumed to be a flat-ended cylinder without deformation. A new theoretical model of deformation is introduced, and based on the energy method, a theoretical formula is derived to estimate the ballistic limit velocity of the process. Numerical simulations of the penetration process of a blunt solid cylinder into the empty metal columns are performed using the LS-DYNA explicit solver. Different empty columns are used as the targets, and these columns are made from Weldox 460E steel and have different wall thicknesses (6, 7, 8 and 9 mm) and internal column edge lengths (60, 70, 80 and 90 mm). To validate the derived relation for the ballistic limit velocity, the results of the numerical simulations are compared with the corresponding theoretical predictions. Finally, the effects of some geometrical characteristics such as projectile diameter and mass on the perforation process and the ballistic limit velocity are discussed.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [24] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [25] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [26] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [27] |

李向东, 杜忠华. 目标易损性[M]. 北京: 北京理工大学出版社, 2013.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

Fig.1 Reactive fragments and quasi-static compressive stress-strain curves

Fig.1 Reactive fragments and quasi-static compressive stress-strain curves Table 1 Mechanical properties of reactive fragments

Table 1 Mechanical properties of reactive fragments Fig.2 Experimental target and target structure schematic

Fig.2 Experimental target and target structure schematic Fig.3 Schematic and image of the experimental test system

Fig.3 Schematic and image of the experimental test system Table 2 Image of typical target damage area

Table 2 Image of typical target damage area Table 3 Experimental results of reactive fragments damage to spacer target

Table 3 Experimental results of reactive fragments damage to spacer target Fig.4 Typical high-speed photographs

Fig.4 Typical high-speed photographs Fig.5 Process of reactive fragments penetrating the plate

Fig.5 Process of reactive fragments penetrating the plate Fig.6 Evolution of post-target debris cloud with different impact velocities

Fig.6 Evolution of post-target debris cloud with different impact velocities Fig.7 Fragmentation, activation and sparse wave unloading size of reactive fragments

Fig.7 Fragmentation, activation and sparse wave unloading size of reactive fragments Fig.8 Relationship between the total kinetic energy and activation degree

Fig.8 Relationship between the total kinetic energy and activation degree Fig.9 Schematic diagram of target plate acted by debris cloud

Fig.9 Schematic diagram of target plate acted by debris cloud Fig.10 Unit debris kinetic energy and reaction mass at the position of rear target through aperture at different impact velocities

Fig.10 Unit debris kinetic energy and reaction mass at the position of rear target through aperture at different impact velocities/

| 〈 |

|

〉 |